#Geotechnical & Structural

Explore tagged Tumblr posts

Text

Unraveling the Growth Potential of the Geofoams Market: Global Outlook

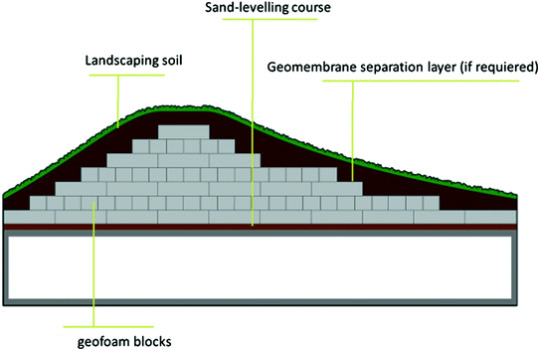

The global geofoams market size is expected to reach USD 972.6 million by 2027, expanding at a CAGR of 2.7%, according to a new report by Grand View Research, Inc. Factors such as availability of geofoams at low cost coupled with its superior strength and durability are projected to fuel the market growth. Expansion of the construction industry across the globe coupled with the infrastructural developments in economies such as India, China, Brazil, Mexico, Saudi Arabia, and others is expected to propel the demand for geofoams over the forecast period. In addition, maintenance of the existing infrastructure in developed nations is likely to drive the growth of the market.

Geofoams Market Report Highlights

The expanded polystyrene geofoams segment accounted for USD 508.2 million in 2019 and is projected to expand at a CAGR of 3.1% from 2020 to 2027. The compatibility of the product has resulted in its increasing adoption for applications including roads and highway construction, building and infrastructure, and others

The road and highway construction application segment accounted for 38.07% of the total market and is projected to expand at a CAGR of 3.4% from 2020 to 2027 on account of the rising infrastructural growth across the developing economies including China, India, Brazil, UAE, Saudi Arabia, and others

Asia-Pacific accounted for USD 278.5 million in 2019 and is estimated to expand at a CAGR of 3.2% from 2020 to 2027 owing to the rising demand for road pavement, which is anticipated to further benefit the growth

China accounted for the highest market share in Asia Pacific on account of the rapidly expanding construction industry in the country

Europe market is estimated to expand at a CAGR of 2.8% owing to the rising number of construction and infrastructural activities in economies including Spain, Italy, and others

For More Details or Sample Copy please visit link @: Geofoams Market Report

Geofoams are increasingly used in the construction industry as it helps in suppressing the noise and vibrations. In addition, it is easy to handle and does not require any special equipment for installation. The product is increasingly used in the railway track systems, below the refrigerated storage buildings, storage tanks, and others to avoid ground freezing.

The geofoams undergo chemical changes when it comes in contact with petroleum solvents. It turns into a glue-type substance, thereby losing its strength. This factor is projected to limit the use of geofoams in the construction industry which is projected to restrict the industry growth over the forecast period.

#Geofoam#Expanded polystyrene (EPS)#Geofoam blocks#Construction materials#Road and highway construction#Retaining walls#Geotechnical engineering#Soil stabilization#Environmental protection#Earthquake resistance#Noise and vibration control#Water management#Hydrostatic pressure#Thermal insulation#Structural stability

12 notes

·

View notes

Text

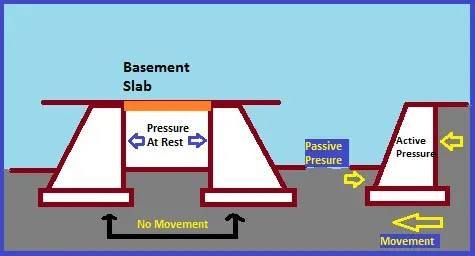

Details of Earth Pressure: Understanding the Forces at Work

When it comes to civil engineering and construction, understanding the behaviour of soil and the forces exerted by it is crucial. Earth pressure is one such fundamental concept that engineers must comprehend to ensure the stability and safety of structures built on or in contact with the ground. This article explores the details of earth pressure, shedding light on the different types, factors…

View On WordPress

3 notes

·

View notes

Text

Rock Anchoring Services in Maharashtra | Anchoring Constructions 9923437177

#Rock anchoring Pune#Rock anchoring Maharashtra#Rock anchoring services Pune#SB Demolition rock anchoring in Maharashtra#Rock anchor installation Pune#Construction rock anchoring in Maharashtra#Structural rock anchoring Pune#Rock anchor contractors Pune#Professional rock anchoring in Maharashtra#Safe rock anchoring services in Maharashtra#Rock stabilization solutions in Maharashtra#Industrial rock anchoring Pune#Geotechnical rock anchoring in Maharashtra#Rock support systems Pune#Rock anchoring for construction projects in Maharashtra

0 notes

Text

Rite Geosystems is Now Encardio Rite: Revolutionizing Geotechnical Monitoring

Big changes are here. Rite Geosystems has officially rebranded as Encardio Rite, USA, bringing over 58 years of global expertise, cutting-edge technology, and a portfolio of iconic projects to the forefront of geotechnical and structural monitoring.

From advanced Nexawave wireless monitoring systems to innovative InSAR remote sensing, we’re setting new standards in infrastructure safety and precision monitoring. Discover how we’re shaping the future of critical infrastructure projects worldwide.

🔗 Check out our journey and solutions here: Visit Website

Let us know your thoughts in the comments!

0 notes

Text

Little P.Eng.'s Comprehensive Seismic Structural Services Aligned with ASCE 7-22 and NBCC Standards

In an era where architectural ambition pushes the limits of engineering, safeguarding structural integrity against natural calamities, particularly seismic activities, becomes paramount. This detailed exposé delves into the sophisticated seismic structural engineering services provided by Little P.Eng., a firm renowned for its compliance with the latest American Society of Civil Engineers (ASCE) 7-22 standards and the Canadian National Building Code (NBCC). Their work spans across Canada and the United States, encompassing a diverse range of buildings and non-structural elements, reflecting the pinnacle of safety, reliability, and innovation in modern construction.

1. Introduction

The unpredictable nature of seismic activities has long posed a significant challenge to the realms of construction and civil engineering. Within this volatile environment, Little P.Eng. has emerged as a beacon of reliability, offering cutting-edge seismic structural engineering services across Canada and the United States. Their adherence to the ASCE 7-22 and NBCC codes ensures not only the structural integrity of vast construction undertakings but also the safety and longevity of non-structural elements, affirming their position at the forefront of seismic resilience in contemporary infrastructure.

2. Understanding Seismic Structural Engineering

2.1. The Science of Earthquake Engineering

Before delving into Little P.Eng.'s specialized services, one must understand the core principles of seismic structural engineering. This discipline focuses on making buildings and non-structural components resistant to earthquake shocks through specialized planning, design, detailing, and, subsequently, construction. It encompasses geological science, material engineering, and structural analysis to develop structures capable of withstanding seismic disturbances.

2.2. Evolution of Seismic Codes: From ASCE 7-10 to ASCE 7-22

Seismic building codes are dynamic, evolving in response to the continuous advancements in engineering research and catastrophic lessons learned from each seismic event. The transition from ASCE 7-10 to ASCE 7-22 is a reflection of this evolution, marking significant strides in risk reduction and structural robustness, emphasizing not just human safety but also post-earthquake functionality and rapid recovery for communities.

3. Little P.Eng.’s Integration of ASCE 7-22 in Seismic Structural Engineering

3.1. Innovations in Seismic Design Philosophies

Little P.Eng. employs a forward-thinking approach to integrate the innovations outlined in ASCE 7-22. These include state-of-the-art seismic design philosophies involving base isolation, energy dissipation devices, and performance-based seismic design (PBSD), allowing for structures that are more flexible, absorb and dissipate seismic energy, and maintain structural integrity during earthquakes.

3.2. Site-Specific Hazard Analysis and Geotechnical Considerations

One of the critical aspects of ASCE 7-22 is the emphasis on site-specific hazard analyses. Little P.Eng.'s engineers led by Meena Rezkallah carry out comprehensive geotechnical evaluations, considering soil-structure interaction, liquefaction potential, and site-specific seismic hazard assessments. By understanding the geological variances across different regions in North America, they ensure that each design is intrinsically aligned with its environmental context.

4. Adherence to NBCC Standards: Expanding Safety Parameters Across Canada

4.1. Bridging Policies between Countries

While their services in the United States predominantly adhere to ASCE standards, Little P.Eng. seamlessly bridges engineering policies between the U.S. and Canada by aligning their practices with the NBCC. This code compliance not only underscores their versatility in handling cross-border projects but also reflects their commitment to upholding the highest safety and professional standards in every geographical locale.

4.2. Understanding NBCC’s Seismic Provisions

The NBCC has distinct seismic provisions, necessitating specialized knowledge and an adaptive engineering approach. Little P.Eng.'s expertise in Canadian seismic codes ensures that structural and non-structural components comply with regional regulations, catering to Canada's unique seismic challenges, especially in high-risk provinces.

5. Comprehensive Services for Buildings and Non-Structural Elements

5.1. Diverse Building Typologies

Little P.Eng.'s portfolio encompasses a variety of buildings, from residential high-rises and expansive commercial complexes to critical facilities like hospitals and emergency response centers. Each building type presents unique challenges, and the firm’s nuanced, context-oriented approach to seismic retrofitting and sustainable design practices sets industry standards.

5.2. Protecting Non-Structural Components

Beyond the buildings themselves, Little P.Eng. extends its engineering prowess to safeguard non-structural elements. These components, often overlooked, can pose significant hazards during seismic events. From architectural elements to mechanical and electrical systems, the firm implements exhaustive strategies to enhance the safety of these components, thereby protecting human life and minimizing economic loss.

6. Future Directions and Continuous Advancements

6.1. Embracing Technological Innovations

As the field of seismic structural engineering advances, Little P.Eng. remains committed to incorporating new technologies, including artificial intelligence and machine learning, for predictive analysis, design optimization, and risk management. Their continual investment in technology positions them as a leader in future-proofing structures against earthquakes.

6.2. Contribution to Global Seismic Safety Standards

Harnessing Advanced Engineering: Little P.Eng.'s Comprehensive Seismic Structural Services Aligned with ASCE 7-22 and CNBCC Standards in North America

7. Conclusion

Little P.Eng.’s comprehensive seismic structural engineering services, grounded in the latest ASCE and NBCC standards, represent a confluence of scientific mastery, innovative engineering, and a deep commitment to safeguarding human lives and investments. Their work across diverse building typologies and non-structural components in Canada and the United States cements their stance as a pivotal player in shaping resilient, sustainable, and safe urban landscapes. As seismic activity remains an unpredictable threat, the foresight and innovation of firms like Little P.Eng. are society's best bet for a safer tomorrow.

References

[1] American Society of Civil Engineers. (2022). Minimum Design Loads and Associated Criteria for Buildings and Other Structures (ASCE/SEI 7-22). ASCE.

[2] National Research Council Canada. (2020). National Building Code of Canada.

Tags:

Little P.Eng.

ASCE 7-22

design optimization

earthquake resilience

energy dissipation

building codes

seismic design

advanced materials

non-structural components

CNBCC

technological innovations

cross-border projects

geotechnical considerations

mechanical systems safety

base isolation

sustainable construction

electrical systems safety

Seismic structural engineering

critical infrastructure

artificial intelligence

urban resilience

construction techniques

seismic retrofitting

site-specific analysis

predictive analysis

professional standards

safety regulations

risk management

performance-based design

global seismic standards

Engineering Services

Structural Engineering Consultancy

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng.#ASCE 7-22#design optimization#earthquake resilience#energy dissipation#building codes#seismic design#advanced materials#non-structural components#CNBCC#technological innovations#cross-border projects#geotechnical considerations#mechanical systems safety#base isolation#sustainable construction#electrical systems safety#Seismic structural engineering#critical infrastructure#artificial intelligence#urban resilience#construction techniques#seismic retrofitting#site-specific analysis#predictive analysis#professional standards#safety regulations#risk management#performance-based design#global seismic standards

0 notes

Text

Discover top engineering service consultants in UAE - TradersFind

Uncover the expertise of top engineering service consultants in UAE through TradersFind and discover reliable engineering service consultancy for your business success. Whether it's construction, infrastructure, or consultancy, find the right expertise here. TradersFind connects you with trusted engineering companies that offer quality services. Visit TradersFind and contact us now!

#engineering services#engineering service consultancy#engineering service consultants#environmental engineering services#geotechnical engineering services#structural engineering services#Engineering Services

0 notes

Text

March 17th 1979 saw a collapse in the Penmanshiel Tunnel near Grantshouse Berwickshire, in the Scottish Borders, two men tragically lost their lives.

Shortly before 3:45 a.m. on 17 March 1979, the duty Railway Works Inspector noticed some small pieces of rock flaking away from the tunnel wall, approximately 90 metres from the southern entrance, He decided that it would be wise to shore up the affected piece of the tunnel and was making his way towards the site office to arrange this when he heard the sound of the tunnel collapsing behind him.

It is estimated that approximately 20 metres of the tunnel arch collapsed, with the resultant rock fall filling 30 metres of the tunnel from floor to roof and totally enveloping a dumper truck and a JCB, along with the two men operating them. Despite efforts to get to the men further falling rock prevented this.

The thirteen other people working inside the tunnel at the time of the collapse were able to escape successfully, but despite the efforts of rescuers (including a specialised mine rescue team) it was not possible to reach the two operators.

What must be more heart-breaking for the families of the two men, Gordon Turnbull and Peter Fowler is that it was deemed too dangerous to try and recover the bodies and the tunnel was sealed and abandoned their remains left buried where they perished.

A report into the collapse could not reach a conclusion on the overall cause due to the abandonment. However, geotechnical investigations of the area surrounding the tunnel found evidence suggesting fracturing of rock overlaying the tunnel and, in particular, an anticlinal structure of shattered and sheared rock intersecting the line of the tunnel in close proximity to the area of the collapse.

The report accordingly concluded that the collapse was likely to be the result of degeneration of the fractured rock overlying the tunnel in the end it stated that as the conditions leading to the collapse could not reasonably be foreseen—there were no grounds for finding any individual responsible for the accident.

Despite the enquiry findings British Railways were fined £10,000 "having failed to ensure that persons in the tunnel were not exposed to the risk of personal injury by the collapse of part of the [tunnel] structure", they did not contest the case pleading guilty to the charges.

A memorial stands directly over the point of the rock fall in tribute to Gordon and Peter, the 3-sided Obelisk bares a plaque dedicated to each of the men, and the 3rd side bares the cross, with the memorial constructed from rock that had fallen that night.

Afterwards the east coast rail line was diverted, a cutting was made, which also meant the A1 road nearby had to be diverted.

8 notes

·

View notes

Text

study girl [4/5]

This week was sooo long. I had a structural analysis exam on Monday. I totally thought I failed, but I got an 89! And fluid mechanics is going so well. I got a 105% on the exam from last week and I know I aced the quiz we took today! I just completed an open note geotechnical exam, and gosh I need a nap.

Saturday morning I’m going to go to the farmers market. Then I’m meeting up with my group to finish our building design. Maybe I’ll go to a party.

xoxo

#study girl#studyblr#study blogger#study blogging#girl blogging#girlblogging#study motivation#it girl#becoming that girl#that girl#light acadamia aesthetic#dark acadamia aesthetic#classic academia#romantic academia

24 notes

·

View notes

Text

Top 5 High-Paying Jobs for Civil Engineers in 2024

The civil engineering sector is evolving rapidly, driven by technological advancements and increasing infrastructure demands. As we move into 2024, civil engineers are presented with numerous lucrative career opportunities. This article highlights the top five jobs for civil engineers in 2024, focusing on their roles, responsibilities, and salary expectations. 1. Construction…

View On WordPress

#BIM engineer positions#civil engineer salary#civil engineering career opportunities#civil engineering job market#Civil engineering jobs 2024#civil engineering specializations#construction manager jobs#environmental engineer jobs#geotechnical engineer careers#highest paying civil engineering jobs#infrastructure development jobs#structural engineer roles#sustainable engineering careers

0 notes

Text

Rock Anchoring Services in Maharashtra | Anchoring Constructions 9923437177

SB Demolition Offers Reliable Rock Anchoring Services in Maharashtra. Ensure Stability And Safety For Your Construction Projects With Our Expert Solutions.

#Rock anchoring Pune#Rock anchoring Maharashtra#Rock anchoring services Pune#SB Demolition rock anchoring in Maharashtra#Rock anchor installation Pune#Construction rock anchoring in Maharashtra#Structural rock anchoring Pune#Rock anchor contractors Pune#Professional rock anchoring in Maharashtra#Safe rock anchoring services in Maharashtra#Rock stabilization solutions in Maharashtra#Industrial rock anchoring Pune#Geotechnical rock anchoring in Maharashtra#Rock support systems Pune#Rock anchoring for construction projects in Maharashtra

0 notes

Text

Metasensing for Megastructures: The Role of Encardio Rite in Building the Shri Ram Temple, Ayodhya

Encardio Rite played a crucial role in the construction of the Shri Ram Temple in Ayodhya, utilizing advanced structural monitoring and geotechnical instrumentation to ensure its integrity and safety.

For more Click here

0 notes

Text

Translation of article with Sakurai Sho from "News Zero". 239 Three months since the Yashio crash New developments at the search site.

On twenty-eight April 2025, it will be exactly three months since the accident that collapsed a road in Yashio, Saitama Prefecture.

New details have emerged at the scene of the search for the driver.

We arrived at the site of the collapse.

-Sakurai: "We saw a big crane behind us. We couldn't go any further from here, so we were told to turn off the street."

With the permission of a nearby company, we looked from the roof.

-Sakurai:-"From above, the building is quite massive. There are some ordinary residential buildings around. You can see that the accident happened in the middle of a residential area."

Three months ago, an accident suddenly occurred on a road in Yashio Prefecture, Saitama.

A ten-metre hole opened up in the middle of the intersection, into which a male truck driver fell.

He is believed to still be stranded.

The next day a second funnel appeared, forming two holes.

The two holes were then joined….

Three days after the collapse, the hole was about forty metres in diameter. The accident is believed to have been caused by corrosion and damage to an underground sewer pipe.

Experts who inspected the scene today.

-Hiroshi Chikaku-san, Geotechnical Systems Research Institute:-"In front of the crane is a steel frame in the shape of a gate. The driver's seat is directly underneath it."

Our attention was drawn to the new frame-like structure that was built on the day of the interview.

In preparation for the rescue, pits were dug on two sides: almost directly above the driver's seat and at an angle.

The new structure was built in the part that was thought to be directly above it.

-Hiroshi Chikaku-san, Geotechnical Systems Research Institute:-"You can dig a hole with this and pull it up with this. I think they think differently."

The driver's section can also be lifted from here. In addition, the key to restarting the search is already in place.

The sewer pipe where the driver's seat is located.

The sewage flowing down it interfered with the search.

So a "temporary drainage pipe" was built to bring the sewage closer.

However, according to the prefecture, the water level has not gone down enough, although by today it had already started flowing in that direction.

Hiroshi Chikaku-san, Geotechnical Systems Research Institute:-"(Sewer pipes) must be dry and ready for construction. It is difficult. If there is no slope, water cannot flow. I think that currently the slope is not constructed correctly."

-Sakurai:-"We are also concerned about rain, as the rainy season is approaching, how does it affect you?"

Hiroshi Chikaku-san, Geotechnical Systems Research Institute:-"That's the biggest concern. I think they rushed it, because if the construction is not completed before the rainy season, it will become a big problem, so rainwater and other water will not flow back…"

-Sakurai:- The road remains closed in all directions at the junction with the flooded road in the vicinity of the site. Some primary schools have been forced to change their route to school, and guides are on duty at the site 24 hours a day to ensure that residents do not mistakenly enter the restricted area.

-Fujii: -The hole wasn't very big at first, but it spread quickly. There were restaurants operating in the area, weren't there?

-Sakurai:- This restaurant, located at that very intersection, has been providing parking spaces for rescue workers since the accident, and also offered the restaurant as a resting place for construction workers. But even now, there is no chance of the restaurant reopening, and employees have moved to other related restaurants or left their jobs. The first priority is to rescue the man and strenuous work continues at the scene.

Source: https://www.ntv.co.jp/zero/kikikomi/articles/9biu28a2a8oelvz1.html

The translation could possibly be incorrect, if anything, you can correct somethig.

#Sakurai Sho#櫻井翔#Arashi#嵐#Translation Of Japanese Article#News Zero#Japanese News Programme#Nippon TV

3 notes

·

View notes

Text

Civil Engineering Review • Week 4

I have finished another book consisting of more or less 300 problems

I also arranged my books and tagged the finished chapters 😁😁

Progress:

•3 Mathematics Sessions

•3 Structural Theory Sessions

•2 Fluid Mechanics Sessions

•3 Geotechnical Engineering Sessions

•3 Surveying Sessions

•2 Short Quizzes

•1 Long Quiz

now I have 4 on going books to solve

Looking forward to week 5 🥰

#studyblr#student life#study blog#student#productivity#civil engineering#days of productivity#board exams#review routine

23 notes

·

View notes

Text

The article from Jagannath University explores top M.Tech specializations for Civil Engineering graduates, such as Structural, Geotechnical, Environmental, Transportation, and Water Resources Engineering. It emphasizes that these fields enhance technical knowledge, opening doors to advanced career opportunities in infrastructure, construction, design, and research within the civil engineering industry.

2 notes

·

View notes

Text

Exploring Large Diameter Pipes – Construction Challenges and Solutions

Understanding Large Diameter Pipes

Large diameter (Dia) pipes are essential components in many infrastructure projects, including water supply systems, sewage treatment plants, and oil and gas pipelines. Their size and functionality enable the efficient transport of large volumes of liquids and gases, making them indispensable in modern construction. However, working with large diameter pipes presents unique challenges that require specialized solutions. Tube Trading, a leading large Dia pipe supplier in Vadodara, has extensive experience in addressing these challenges. This article explores the construction challenges associated with large diameter pipes and the solutions provided by industry leaders like Tube Trading, a prominent large Dia pipe dealer in Vadodara and a reliable large Dia pipe distributor in Gujarat.

Large diameter pipes are typically defined as pipes with a diameter of 24 inches (600 mm) or more. They are made from various materials, including steel, ductile iron, concrete, and plastic, each offering specific advantages depending on the application. These pipes are used in a variety of sectors, such as:

Water and Wastewater: For transporting potable water and sewage.

Oil and Gas: For transporting crude oil, natural gas, and refined products.

Industrial Applications: For transporting chemicals, slurry, and other industrial fluids.

Construction: As structural elements in large infrastructure projects.

Construction Challenges of Large Diameter Pipes

The installation and maintenance of large diameter pipes pose several challenges, which include:

1. Transportation and Handling

Transporting and handling large diameter pipes can be logistically complex due to their size and weight. These pipes often require special equipment and careful planning to ensure they are transported safely and efficiently.

Solution: Tube Trading, as a leading large Dia pipe distributor in Gujarat, uses specialized transportation methods and equipment to handle large diameter pipes. This includes flatbed trucks, cranes, and forklifts designed to accommodate the size and weight of these pipes. Their logistics team ensures that transportation complies with all safety regulations and standards.

2. Site Preparation and Trenching

Proper site preparation and trenching are critical for the successful installation of large diameter pipes. This involves clearing the site, excavating trenches, and ensuring that the ground conditions are suitable for pipe laying.

Solution: Tube Trading provides comprehensive site assessment and preparation services. They use advanced geotechnical surveys to analyze soil conditions and design appropriate trenching solutions. This minimizes the risk of ground instability and ensures a solid foundation for the pipes.

3. Jointing and Welding

Joining large diameter pipes securely is essential to prevent leaks and ensure the integrity of the pipeline. This can be particularly challenging with materials like steel, which require precise welding techniques.

Solution: As a top large Dia pipe dealer in Vadodara, Tube Trading offers expert welding and jointing services. Their team of certified welders uses state-of-the-art welding equipment and techniques to ensure strong, leak-proof joints. For non-metallic pipes, they provide specialized coupling systems that offer reliable connections.

4. Pressure Testing and Quality Assurance

Large diameter pipes used in critical applications, such as water supply and oil and gas transport, must undergo rigorous pressure testing to ensure they can withstand operational pressures without failing.

Solution: Tube Trading conducts thorough pressure testing and quality assurance checks on all pipes before installation. Their testing procedures comply with international standards, ensuring the pipes’ durability and reliability. This includes hydrostatic testing, where pipes are filled with water and pressurized to detect leaks and weaknesses.

5. Corrosion Protection

Corrosion can significantly reduce the lifespan of large diameter pipes, especially those made from metal. Protecting these pipes from corrosion is essential for long-term durability and performance.

Solution: Tube Trading offers a range of corrosion protection solutions, including coatings, linings, and cathodic protection systems. These measures protect the pipes from environmental factors and extend their service life. Their experts recommend the most suitable protection method based on the pipe material and operating conditions.

6. Environmental and Regulatory Compliance

Construction projects involving large diameter pipes must comply with environmental regulations and standards to minimize their impact on the environment.

Solution: Tube Trading is committed to environmentally responsible practices. They ensure all their projects comply with local and international environmental regulations. This includes using environmentally friendly materials and methods, as well as implementing measures to protect natural habitats and water sources during construction.

Innovative Solutions by Tube Trading

Tube Trading’s extensive experience and expertise in handling large diameter pipes make them a trusted partner for construction projects in Vadodara and Gujarat. Here are some innovative solutions they offer:

1. Custom Pipe Fabrication

Tube Trading provides custom fabrication services to meet specific project requirements. This includes custom lengths, bends, and fittings that ensure seamless integration with existing infrastructure. Their fabrication facilities are equipped with the latest technology to deliver high-precision products.

2. Comprehensive Project Management

From initial planning to final installation, Tube Trading offers comprehensive project management services. Their team of experts oversees every aspect of the project, ensuring timely completion and adherence to budget. This integrated approach minimizes disruptions and ensures smooth project execution.

3. Advanced Material Solutions

Tube Trading supplies a variety of pipe materials, including high-density polyethylene (HDPE), polyvinyl chloride (PVC), and ductile iron. Each material is chosen based on the specific needs of the project, offering optimal performance and cost-effectiveness. Their material experts provide guidance on selecting the best material for each application.

4. Technical Support and Training

Tube Trading provides technical support and training to ensure that construction teams are well-equipped to handle large diameter pipes. This includes training on installation techniques, safety procedures, and maintenance practices. Their support services ensure that clients have the knowledge and resources needed for successful project execution.

Why Tube Trading Stands Out

As a premier large Dia pipe supplier in Vadodara, Tube Trading has built a reputation for excellence and reliability. Their commitment to quality, innovation, and customer satisfaction sets them apart in the industry. Here’s why Tube Trading is the preferred choice for large diameter pipe solutions:

1. Extensive Industry Experience

With years of experience in the industry, Tube Trading has developed deep expertise in handling large diameter pipes. Their extensive portfolio of completed projects demonstrates their capability and reliability.

2. Quality Assurance

Tube Trading adheres to the highest quality standards in the industry. Their products undergo rigorous testing and inspection to ensure they meet or exceed client expectations. This commitment to quality ensures that clients receive durable, high-performance pipes for their projects.

3. Customer-Centric Approach

Tube Trading’s customer-centric approach ensures that clients receive personalized solutions tailored to their specific needs. Their team works closely with clients to understand their requirements and provide the most effective solutions.

4. Comprehensive Solutions

From supply and fabrication to installation and maintenance, Tube Trading offers end-to-end solutions for large diameter pipes. This comprehensive approach simplifies project management and ensures seamless execution.

Conclusion

Large diameter pipes are critical components in many infrastructure projects, but they come with unique construction challenges. Addressing these challenges requires specialized expertise and innovative solutions. Tube Trading, a leading large Dia pipe supplier in Vadodara, excels in providing comprehensive solutions that ensure successful project execution. Their commitment to quality, innovation, and customer satisfaction makes them a trusted partner for large diameter pipe projects in Vadodara and Gujarat. Whether you need custom fabrication, technical support, or comprehensive project management, Tube Trading is your go-to large Dia pipe dealer in Vadodara and a reliable large Dia pipe distributor in Gujarat.

#Large dia pipe distributor in Gujarat#Large dia pipe supplier in Vadodara#Large dia pipe dealer in Vadodara

4 notes

·

View notes

Text

Exploring the Depths: The Role of Geotechnical Drilling in Modern Construction

In the rapidly evolving world of construction and civil engineering, geotechnical drilling stands as a cornerstone technique, critical for ensuring the safety, stability, and success of any infrastructure project. At Matrix Drilling, we specialize in providing top-tier geotechnical drilling services, tailored to meet the unique challenges of each site and project. This article will delve into what geotechnical drilling is, its importance in construction, and how Matrix Drilling leads the industry in delivering reliable and effective drilling solutions.

What is Geotechnical Drilling? Geotechnical drilling is a specialized form of drilling that is conducted to investigate the physical properties of a site's subsurface. This process is essential for gathering vital data that helps engineers determine the suitability of the ground for proposed construction projects. The primary goal of geotechnical drilling is to reduce uncertainty and provide engineers with detailed information about the soil composition, rock profiles, groundwater levels, and other critical factors that could impact the structural integrity of a building or structure.

The Importance of Geotechnical Drilling in Construction Site investigation and assessment are paramount before any construction can commence. Geotechnical drilling is integral in this phase, offering precise data that can highlight potential issues such as unstable soil, voids, or high groundwater levels. This information is crucial for engineers to design foundations and structural elements that are both safe and economical.

The insights gained from geotechnical drilling allow architects and engineers to optimize their designs to suit the specific conditions of the soil and subsurface environment. This can lead to a more efficient use of materials and the adoption of innovative construction techniques that might not have been considered without the data provided by geotechnical drilling.

Moreover, geotechnical drilling aids in risk mitigation by forecasting potential challenges that might arise during construction. This proactive approach prevents costly delays, redesigns, and enhances overall safety. It also plays a vital role in environmental conservation by assessing the impact of construction on the subsurface environment, ensuring that the natural habitat and water sources are preserved or minimally disturbed.

Matrix Drilling: A Leader in Geotechnical Drilling Services At Matrix Drilling, we pride ourselves on our ability to handle the most challenging geotechnical projects with precision and efficiency. Our use of state-of-the-art drilling rigs and technology ensures high accuracy and efficiency in our drilling operations. Our equipment is capable of penetrating a variety of soil types and rock formations, ensuring comprehensive data collection even under difficult conditions.

Our team of geotechnical experts brings extensive experience in both onshore and offshore drilling, offering a depth of knowledge that is unmatched in the industry. This expertise ensures that all projects are executed with the highest standards of quality and safety.

We understand that every site is unique, which is why we provide customized drilling solutions designed to meet the specific needs and challenges of each project. Whether it's a high-rise building, a bridge, or a residential complex, we tailor our methods to ensure optimal outcomes.

Safety is at the core of everything we do at Matrix Drilling. We adhere to strict safety protocols to protect our team, the public, and the environment. Our operations are conducted with minimal environmental impact, preserving the ecological balance of the areas we work in.

Last Word: Geotechnical drilling is more than just a preliminary step in construction; it is a fundamental practice that supports the entire building process from conception to completion. At Matrix Drilling, we understand the critical role this service plays in ensuring the success of construction projects. By leveraging our advanced technology, extensive expertise, and a commitment to safety, we provide our clients with the confidence that their projects are built on solid ground. For those looking to explore the depths beneath the surface, Matrix Drilling is your trusted partner in uncovering the secrets that will ensure your project's success.

2 notes

·

View notes